Functional, Security, and Aesthetic Coatings and Ink Products for Graphic Arts and Adhesives Markets

Chapter 1: Introduction to Coatings and Ink Products

Functional, security, and aesthetic coatings and ink products play an essential role in the graphic arts and adhesives markets. These products are designed to enhance the visual appeal, protection, and functionality of various surfaces, including paper, plastics, metals, and textiles.

Chapter 2: Functional Coatings and Inks

Functional coatings and inks are engineered to provide specific properties and functionalities to printed materials. They can offer protection against moisture, abrasion, UV radiation, and chemicals. Moreover, these coatings can improve the durability, printability, and adhesion of inks. Examples of functional coatings include varnishes, laminates, and anti-static coatings.

Section 2.1: Varnishes

Varnishes are transparent coatings that are applied to printed materials to enhance their appearance and provide surface protection. They can add gloss, matte, or satin finishes, as well as offer resistance to scratching and fading. Varnishes can be applied using various methods, including roller coating, spray coating, and UV curing.

Section 2.2: Laminates

Laminates are thin protective films that are bonded to printed materials to provide additional strength and resistance against wear and tear. They can be glossy or matte and are commonly used for high-quality packaging, labels, and graphics. Laminates can also offer protection against moisture, chemicals, and UV radiation.

Section 2.3: Anti-Static Coatings

Anti-static coatings are designed to prevent the accumulation of static charges on printed materials. These coatings reduce the risk of electrostatic discharge, which can cause damage to electronic components and attract dust and dirt. Anti-static coatings are commonly used in the production of electronic labels, packaging, and signage.

Chapter 3: Security Coatings and Inks

Security coatings and inks are utilized to protect sensitive documents, products, and packaging from counterfeiting and tampering. These coatings incorporate various security features, such as holograms, watermarks, microprinting, and invisible inks, to ensure authenticity and deter forgery.

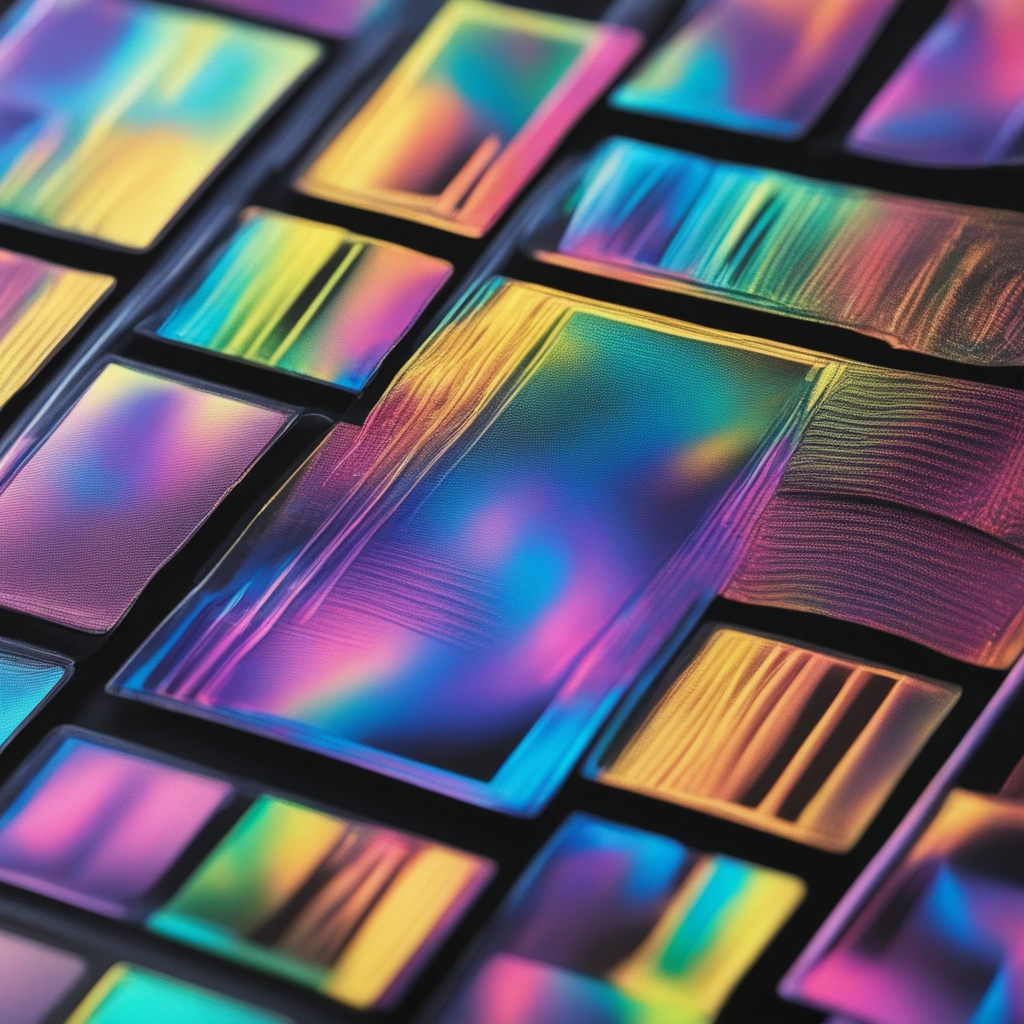

Section 3.1: Holographic Coatings

Holographic coatings contain hologram patterns that create a three-dimensional visual effect, making it difficult to replicate. These coatings are commonly used to secure high-value documents, including banknotes, certificates, and tickets, as well as to protect luxury products from counterfeiting.

Section 3.2: Watermark Coatings

Watermark coatings utilize translucent patterns embedded within the coating layers to create a visible mark when held against light. These coatings are widely used in security papers, passports, and identity cards to authenticate the documents and prevent forgery.

Section 3.3: Microprinting and Invisible Inks

Microprinting is a security feature that involves printing tiny, intricate text or images that are difficult to reproduce accurately. Invisible inks, on the other hand, are only visible under specific lighting or when exposed to certain chemicals. These security measures are commonly employed on valuable documents, bank checks, and product packaging.

Chapter 4: Aesthetic Coatings and Inks

Aesthetic coatings and inks are used to enhance the visual appearance of printed materials, making them more attractive and appealing to the target audience. These coatings can provide unique textures, special effects, and finishes that elevate the overall design and appeal of various graphic arts and adhesives applications.

Section 4.1: Textured Coatings

Textured coatings add tactile elements to printed materials by creating embossed or raised patterns on the surface. These coatings can simulate the texture of materials such as leather, fabric, wood, or stone, enhancing the visual and sensory experience of the end-users.

Section 4.2: Metallic and Pearlescent Coatings

Metallic and pearlescent coatings impart a metallic or iridescent sheen to printed materials, creating a luxurious and eye-catching effect. These coatings are widely used in packaging, labels, signage, and promotional materials to enhance brand recognition and product appeal.

Section 4.3: Specialty Finishes

Specialty finishes include various effects such as glitter, fluorescent, phosphorescent, and thermochromic properties. These coatings and inks are used to create captivating and dynamic visual effects, making the printed materials stand out and capture the attention of the audience.

Leave a Reply